On a global scale, Greece is the third larger producer of olive oil. It is however the only producer that achieves 80% production of Extra Virgin Olive Oil of the finest quality. Why? Well for one Greece is blessed with calcareous soil and the mild Mediterranean climate. It is also blessed with rough landscapes that led to fragmentation of rural land, small fields which made olive oil production in Greece a family business. This guarantees that the olives are collected on time and processed immediately. So until olive oil is collected by traders it is literally pampered in the hands of every producer.

The factors that affect the quality of Extra Virgin Olive Oil are shaping the product’s organoleptic and chemical profile. However, according to evidence provided by recent market research projects about 50% of the consumers surveyed do not know what are the characteristics that influence the quality of olive oil, and why is quality such an important factor. Our aim is to provide you with a guide that will help you assess good Extra Virgin Olive Oil, by evaluating its organoleptic and chemical profile, factors that directly affect its quality.

The color of olive oil is an organoleptic characteristic, such as its taste and aroma. The color of olive oil ranges between golden green to golden depending on the amount of chlorophyll which is determined by how ripe are the olives when collected. Semi-ripe olives have more chlorophyll, while ripe olives contain more carotene, and this influences the color of the olive oil.

The clarity is another important factor. Uniformly cloudy textures indicate that the oil has not been processed apart from a simple paper filtration which is used to remove foreign bodies that might have remained in the oil after extraction.

The process is very similar to tasting wine. To taste olive oil you have to take a small sip in your mouth. Play with in in your mouth to make the oil spread evenly in side. With your teeth shut, touch with the tip of your tongue the back teeth, open your lips lightly and breathe in and out 2-3 times using your diaphragm. This is done to spread the oil evenly in your mouth, swallowing will finalize the process. Remember the tastes you have experienced. You can re-taste olive oil 5 minutes later after cleaning your mouth with water, by eating bread or a piece of apple.

The results of the tasting – organoleptic test

Positive characteristics

• Fruity. Flavor which is reminiscent of both the odour and taste of sound- healthy, fresh fruit picked at its optimum stage of ripeness.

• Bitter. Characteristic of taste of oils obtained from green olives or olives turning colour. It can be more or less pleasant depending on its intensity.

• Spicy – Piquant. Typical among some olive varieties, collected at the start of the crop.

These 3 are the main positive characteristics, positive are also considered the following

• Almond. This flavor may appear in two forms: that typical of the fresh almond or that peculiar to dried, sound almonds which can be confused with incipient rancidity. A distinctive taste is perceived as an aftertaste when the oil remains in contact with the tongue and the palate. This flavor is mainly associated with sweet oils which tend to have a flat odor.

• Sweet. Pleasant taste, not exactly sugary, but found in oil in which the bitter, stringent and pungent attributes do not predominate.

• Ripely fruity. Subtle smell and semisweet taste, originating from healthy mature olives.

• Apple. This is a characteristic flavor of olive oil which is reminiscent of apple fruit.

• Harsh. Characteristic sensation of certain oils which, when tasted, produce a mouth-feel reaction of astringency.

• Grass. Characteristic of certain oils reminiscent of recently-mown grass.

Negative characteristics

• Atrojado – Fusty. Characteristic flavor of oils obtained from olives stored in piles which have undergone an advanced stage of fermentation.

• This is a flavor reminiscent of wine or vinegar characterizing certain oils, mainly due to the formation of acetic acid, ethyl acetate and ethanol in larger amounts than is usual in the aroma of olive oil.

• Metallic. Flavor that is reminiscent of metal, a characteristic of oils which have been in prolonged contact under unsuitable conditions, with foodstuffs or metallic surfaces during crushing, mixing pressing or storage.

• Mustiness – humidity. This is a flavor characteristic of fruit in which a large number of fungi and yeast developed before its processing, as a result of being stored in piles, in humid conditions for several days.

• Rancid. Characteristic flavor to all oils and fats that have undergone a process of auto-oxidation caused by prolonged contact with the air. This flavor is unpleasant and cannot be corrected.

• Heated or burnt. Characteristic flavor of oils caused by excessing and/or prolonged heating during processing, particularly when the paste is thermally mixed, if this is done under unsuitable conditions.

• Hay. Characteristic flavor of certain oils reminiscent of more or less dried grass

• Cucumber. Flavor produced when an oil is hermetically packed for too long, particularly in tin containers, and which is attributed to the formation of 2,6 nonadienal.

Carbohydrates (squalene and terpinikes alcohols and sterols) are the 3 to 3.5% oil. Squalene appears to have deterrent effect on the development of breast cancer. Terpinikon alcohol seems to help remove cholesterol from blood.

The pigments (carotenoids and chlorophyll) and sterols in combination with the phenols prevent the oil to go rancid when exposed to light. The sterols (particularly beta-sitosterol) block the absorption of cholesterol. Carotenes and chlorophyll enhance metabolism, cell growth and healing.

The phenols, polyphenols and phenolic acids have high antioxidant properties and protect the oil from oxidation and free radical creation during the high temperatures of cooking.

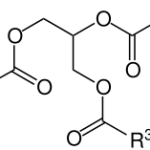

Triglycerides, are created by three saturated fatty acids and glycerin. Under the influence of lipase enzymes this very vulnerable composition breaks and changes into glycerol and free fatty. This increases the acidity of the oil and creates what we call rancidity. This chemical reaction is the most serious damage that olive oil experiences.

Olive oil is also rich in Vitamin E known for its important role in the protection of osteoporosis in women and men.

Olive oil production and usage in Greece dates back for thousand years. It has been appreciated greatly for its nutritional, medicinal and other properties. It is no surprise that there are many varieties of olive trees in Greece, many of them used for olive oil production. The results are very much different not only between varieties, but also between similar varieties cultivated in different microclimates and soil compositions.

The main olive tree varieties cultivated in Greece are:

• Koroneiki variety (Olea Europea var. microcarpa alba), considered the queen of all Greek varieties, this small size olive is relatively non demanding in terms of water, producing stable and good yield per tree. The oil from this variety has intense aroma and flavor, with fruity bitter tones.

• Athinolia variety, is more sensitive and requires more cultivating efforts, it is resistant to cold temperatures, but with medium production yields. The oil originating from this variety has deep fruity flavor and a great amount of aromatic compounds that enhance the distinctive peppery taste.

• Ladolia, is a variety that lives at poor rocky soil. It produces oil with mild, smooth fruity taste and unique flavor that brings to mind apples, tomatoes or sometimes almonds, ingredients that make the Greek olive variety Ladolia so unique.

• Manaki variety has a larger fruit and is used for oil production and table olive production. The oil of this variety is of excellent quality, with fruity notes and peppery taste. • Mavrolia variety cultivated in Peloponnese and Crete, provides excellent quality olive oil of golden colour and milder sweet flavor, with balanced aromas.

Quality Factors

There are numerous other varieties with no specific cultivating interests.

Generally speaking, the first pressing tends to produce oil with the highest quality and olives that undergo a second or third pressing are likely to produce oils that decrease in quality with each pressing. Oil quality is also influenced by timing. The olive-harvest date is critical in order to achieve the highest quality oil. The harvest usually takes place in late autumn when the olives have reached their optimum level of maturity and oil levels are deemed to be peaking. In addition, olives should ideally be processed relatively soon after harvesting, usually within 48 hours. Storage times need to be long enough to allow the olives to become warm, so that they release their oil easily, but short enough to avoid detrimental effects caused by fermentation during the olives’ natural degradation.

Extraction Process

Another key determinant of oil quality is the type of production process used. Methods for extracting and processing oil from raw olives vary. They range from niche artisan approaches and traditional techniques to large scale commercial systems that apply high-tech industrial manufacturing processes. The basic steps involved in all of these processing methods are however similar. The first stage involves grinding or crushing the olives (often including the stones). This crushed olive paste (referred to as ‘pomace’) is then pressed to produce a liquid substance, which is finally separated into oil, water and solid elements. Different techniques are used to crush, press and separate the oils. The main manufacturing processes favored by EU olive oil mills can be grouped into three methodological approaches. These are:

• Traditional methods – combining stone milling and mechanical-pressing techniques

• The two-phase decanter process – based on a horizontal centrifuge system used to separate and extract oils; and

• The three-phase decanter process – also based on horizontal centrifuge technology and involving an additional vertical centrifuge phase. On average, these techniques can produce around 200 kg of oil from one tonne of processed olives. This equates to approximately 1 litre of oil from around 2 000 olives.