We provide 2 kinds of extra virgin olive oil, Filtered & Unfiltered. Let’s see where they differ in their production process.

Olive harvest

One of the keys to achieving the best result of oil extraction is the appropriate harvest period of the olives as well as the time of their transportation to the olive mill. Due to the complex landscape, most of the olives in Greece are collected by hand. Then we place them in jute sacks, through which they are transported directly to our olive mill.

Cleaning, pressing, mollification

Once it arrives at the mill, they are temporarily stored, remove the leaves, collected in an area. Then, the olives washing with potable water and approved by the Quality control manager, weighed, pressed, mollificated at a temperature 27o C with potable water.

The preparation of olive paste is one of the most critical stages in determining the quality of the olive oil produced. Fermentation is the process of slowly stirring and mixing ground olives, usually for 20 to 40 minutes. Stirring allows small droplets of olive oil released by the milling process to aggregate and separate more easily. Fermentation is always carried out under controlled atmospheric pressure to maintain the high quality and nutritional value of extra virgin olive oil.

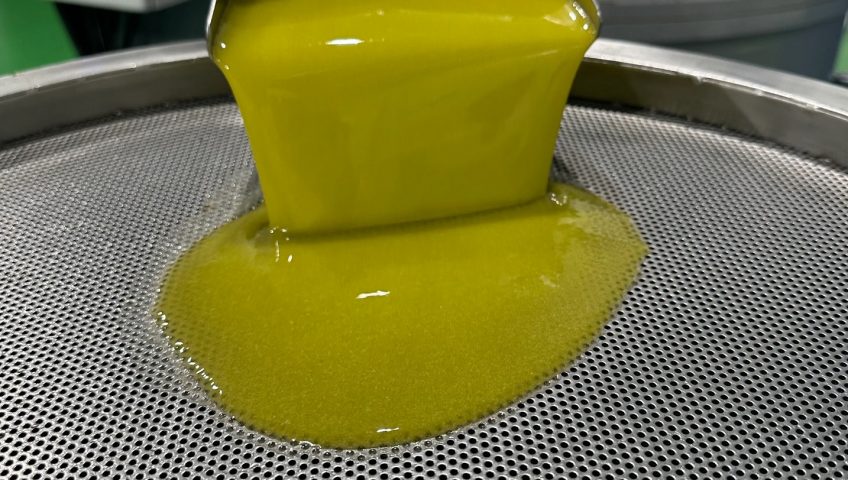

Remove solids & water

They go through the 1st stage of centrifugal purification (removed solid). With the help of centrifugation, divide the olive oil into two phases from the rest of its ingredients. The olive oil coming from the first centrifuge is further processed into a 2nd centrifuge that rotates faster to eliminate any traces of solids and water. Thus, automatic cleaning is carried out to remove sediment.

There they are divided into οlive milling for a third party person and olive milling on behalf of the unit. For a third party person, the following follows, inox standby tank, packaging in metal tins, loading & transportation.

On the other hand, on behalf of the unit, withholding oil/ olive milling fee and storage in inox tanks. Extra Virgin Olive oil should not come into contact with oxygen and light. So, we use inox tanks, which are the most reliable solution for storing olive oil since a good quality of stainless steel doesn’t affect its quality.

If the olive oil is produced at the olive mill, transported to the bottling facility with tanks. But if the olive oil is supplied by trader, we receive it and store it in inox tanks.

Extra Virgin Olive oil filtration

In both cases, if we want to have filtered extra virgin olive oil, follow the following procedure.

1o Filter at p<3atm

2o Paper filter at p<2.5 atm

Packaging

After receiving the packaging materials

-bottling of metal tins >5l, filling from head

-bottling of glass bottles or pet, structure & air supply >3bar, then filling from head.

For both of them, we place lids, check bottle cracking, sign (best before and lot no), package at cartons, palletize, storage and the order loaded on vehicles of transport companies. All this is monitored and approved by the Quality control manager. Then the retailer places them on the shelf and that’s how they reach our table.

We use glass bottles with dark green (especially) color and UV protection, so as not to be affected by sunlight. This is the usual way of distribution to the final consumer. The packaging of olive oil must be a glass bottle or a stainless steel container that closes airtight. We use nitrogen to fill the empty space in the tanks so that the olive oil is not exposed to air. Airtight packaging with a safety cap is also necessary to prevent adulteration.

Filtered vs Unfiltered Extra Virgin Olive Oil

95% of the extra virgin olive oil on the shelves is filtered extra virgin olive oil. But there are also those who wish to taste unfiltered extra virgin olive oil, where this category of olive oil doesn’t go through the 2 steps above mentioned. Those consumers who prefer unfiltered, believe that it contains a richer taste and aroma and retains better polyphenols than filtered. Polyphenols are a type of bioactive compound present in olive oil that are responsible for many of olive oil’s health benefits.

Unfiltered Extra virgin olive oil is opaque and cloudy due to the solid residues present in the oil, while filtered extra virgin olive oil is brighter and more transparent, without impurities.

Unfiltered extra virgin olive oil is more susceptible to the effect of heat and light and should be consumed faster than filtered extra virgin olive oil.

Filtered Extra Virgin Olive Oil has a purer taste and aromas, has minimal effect on the content of polyphenols and other beneficial compounds, and prolongs the shelf life of the oil.

In any case, the choice of filtered or unfiltered extra virgin olive oil is a matter of taste and personal preference.